STAINLESS sTEEL

Machining is a manufacturing process that removes material from a workpiece to create precise parts or components. It typically involves tools like lathes, mills, or CNC machines.

- 1-Axis Machining: Movement along a single linear axis (e.g., X-axis), used for simple operations like drilling or turning on a lathe.

- 2-Axis Machining: Adds a second linear axis (e.g., X and Y), enabling basic milling or cutting of flat surfaces.

- 3-Axis Machining: Incorporates three linear axes (X, Y, Z), allowing for complex 3D shapes, such as pockets or contours, in CNC milling.

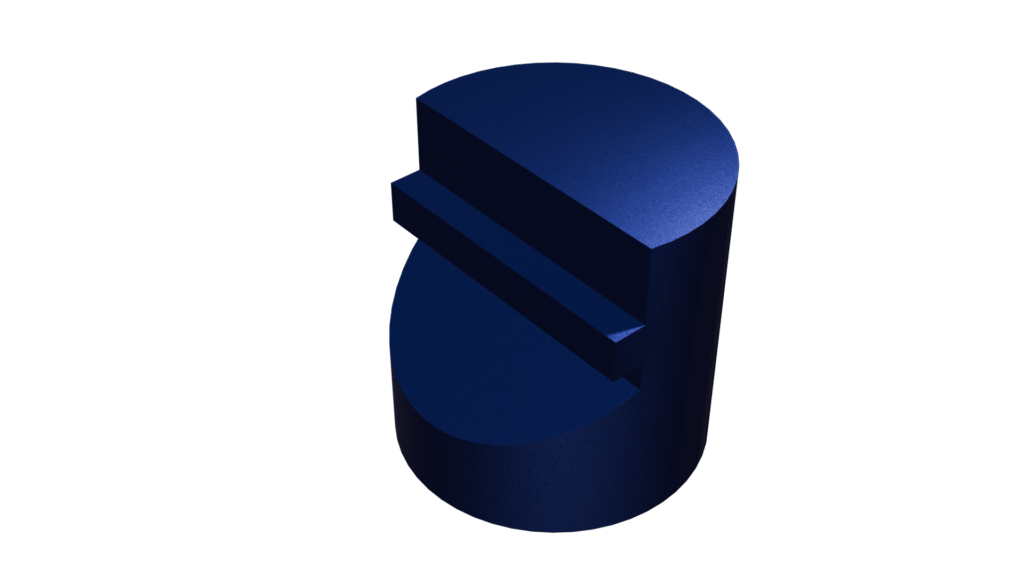

- 4-Axis Machining: Adds one rotational axis (e.g., A-axis) to 3-axis machining, enabling work on cylindrical parts or features from multiple angles without repositioning.

- 5-Axis Machining: Uses three linear axes (X, Y, Z) and two rotational axes (e.g., A and B), offering high precision and flexibility for complex geometries, like aerospace components, by machining multiple sides in one setup.

Each additional axis increases complexity, precision, and efficiency, with 5-axis machining being ideal for intricate, high-tolerance parts.